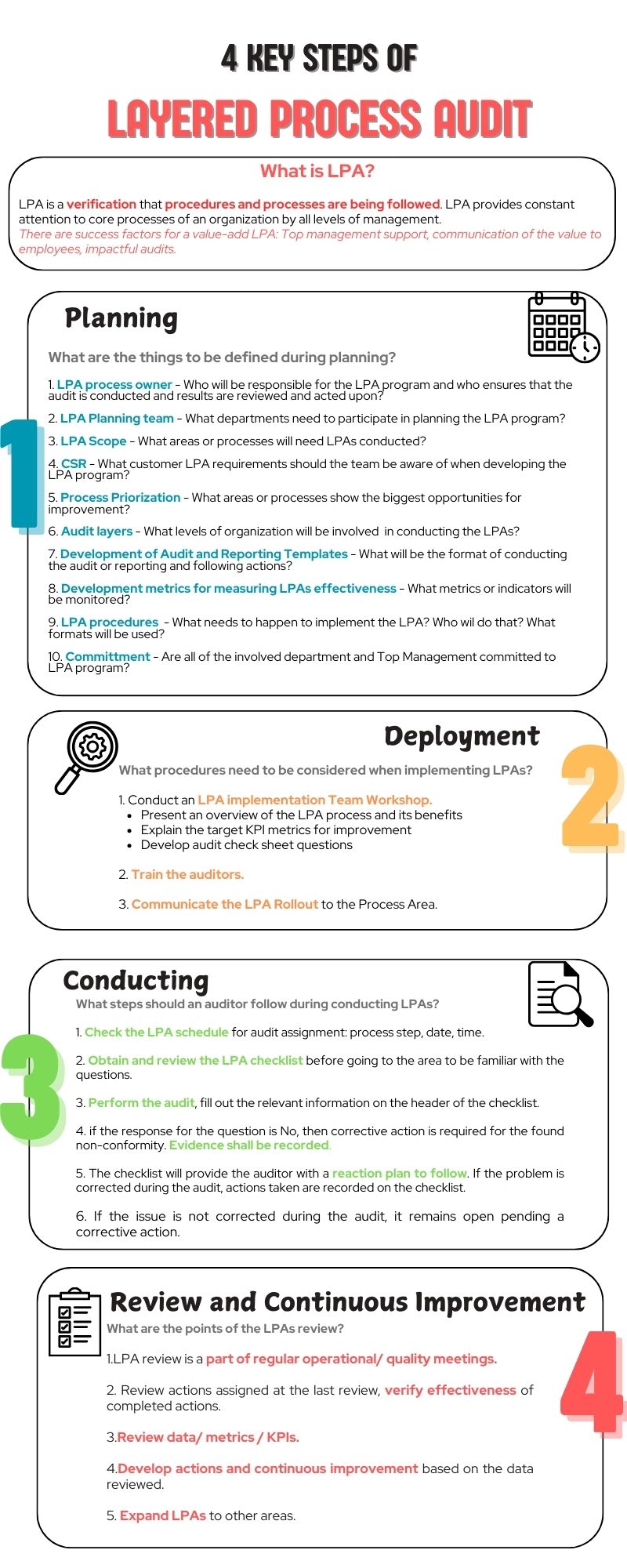

Key steps and benefits of Layered Process Audit

The Layered Process Audit (LPA) is a structured and systematic approach used in manufacturing and production environments to ensure that processes are followed consistently and that quality standards are maintained. The audits are typically “layered” in the sense that different people (e.g., operators, supervisors, managers) perform audits at different levels within the organization, ensuring a comprehensive review of the process.

Requirements for Layered Process Audits

- The LPA is primarily a requirement from automotive and manufacturing industries, AIAG CQI-8:2014 is about the layered Process Audits Guidline.

- Aerospace Industry (AS9100:2016): Similar to the automotive industry, the aerospace sector also uses LPAs.

Key steps of LPAs according to AIAG CQI-8

What are the benefits of LPA?

- Improving product quality and customer satisfaction,

- mitigating safety incidents, reducing waste,

- reducing errors, scrap, reworks;

- increasing first time capability,

- measuring and encouraging work process standardization,

- reinforcing key and updated process steps,

- increasing interactions between the management and operation level,

- allowing first hand feedback from operators to management,

- pursueing continuous improvement,

- reducing the overall cost of poor quality,

- institutionalizing training and process knowlegde.

The Layered Process Audit (LPA) is a structured auditing methodology used to ensure process adherence, product quality, and continuous improvement in manufacturing environments. It is especially critical in industries with high regulatory and quality demands, such as automotive and aerospace.